SOLID CARBIDE END MILLS

Solid Carbide End Mills were developed for machining tough work hardening metals,

stainless steel, titanium, monel, inconel, and super alloys. They are extremely shock resistant.

There are two cutting styles. Non-center cutting (side cutting only) and center grinding (side and end plunge cutting).

They are available with two, three and four flutes.

More flutes reduces chip load and can improve the surface finish. End mills may be a single end or double end design.

Note: Our 6 & 8 flute end mills are only available in High Speed Steel.

Looking for High Speed Steel End Mills? Click Here

CHOOSE AN END MILL CATEGORY/TYPE

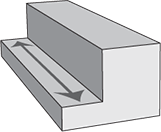

SQUARE END

Square End Style Cut

Square Cut Style End Mills are the most common type of end mill. They are designed to mill square slots, pockets, and edges. Single end mills have one cutting end, while double end mills have two cutting ends, doubling the life of the tool. Most of our solid carbide end mills are also available with a Titanium Nitride (TiN) Coating for working in harder material and for longer production runs. They are more resistant to wear than uncoated end mills.

2 FLUTE

Using two flutes allows for maximum chip ejection. All our solid carbide 2 flute end mills are center cutting.

STUB LENGTH

Double End - 2 Flute - Solid Carbide - Metric

page 274

REGULAR LENGTH

Single End - 2 Flute - Solid Carbide

page 270

Single End - 2 Flute - Solid Carbide - Metric page 274

Double End - 2 Flute - Solid Carbide page 270

LONG LENGTH

Long length style end mills are used when a longer reach is required to mill slots or pockets.

Single End - 2 Flute - Solid Carbide - Long Length page 271

3 FLUTE

Three flutes remove more material per revolution than two flute end mills. They track straighter, mill at very high feed rates, and create a smoother finish than 2 flute end mills. All 3 flute end mills are center cutting.

REGULAR LENGTH

Single End - 3 Flute - Solid Carbide

page 276

4 FLUTE

Using four flutes provides a finer finish than two flutes and operates with less vibration when run at high speeds. All solid carbide 4 flute end mills are center cutting.

STUB LENGTH

Double End - 4 Flute - Solid Carbide - Stub Length

page 273

Double End - 4 Flute - Solid Carbide - Stub Length - Metric page 274

REGULAR LENGTH

Single End - 4 Flute - Solid Carbide

page 272

Double End - 4 Flute - Solid Carbide page 272

LONG LENGTH

Single End - 4 Flute - Solid Carbide - Long Length

page 273

EXTRA LONG LENGTH

Single End - 4 Flute - Solid Carbide - Extra Long Length

page 273

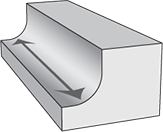

BALL END

Ball End Style Cut

The Ball Nose End Style is used for round bottom holes or slots, and contour milling. Most of our end mills are also available with a Titanium Nitride (TiN) Coating for working in harder material and for longer production runs. They are more resistant to wear than uncoated end mills. Other coatings are available where indicated.

2 FLUTE

Using two flutes allows for maximum chip ejection.

STUB LENGTH

Single Ball End - 2 Flute - Solid Carbide - Stub Length

page 271

Double Ball End - 2 Flute - Solid Carbide - Stub Length - Metric page 274

REGULAR LENGTH

Single Ball End - 2 Flute - Solid Carbide

page 270

Single Ball End - 2 Flute - Solid Carbide - Metric page 270

Double Ball End - 2 Flute - Solid Carbide page 270

3 FLUTE

Three flutes remove more material per revolution than two flute end mills. They track straighter, mill at very high feed rates, and create a smoother finish than 2 flute end mills.

REGULAR LENGTH

Single Ball End - 3 Flute - Solid Carbide

page 276

Single Ball End - 3 Tapered Flutes - Solid Carbide (non-center cutting) page 277

4 FLUTE

Using four flutes provides a finer finish than two flutes and operates with less vibration when run at high speeds.

STUB LENGTH

Single Ball End - 4 Flute - Solid Carbide - Stub Length

page 273

Double Ball End - 4 Flute - Solid Carbide - Stub Length - Metric page 275

REGULAR LENGTH

Single Ball End - 4 Flute - Solid Carbide

page 275

Single Ball End - 4 Flute - Solid Carbide - Metric page 272

Double Ball End - 4 Flute - Solid Carbide page 272

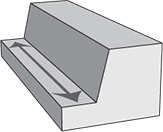

TAPERED FLUTE

Tapered Style Cut

Tapered End Mills are designed with a constant spiral to prevent chatter during use and to resist side thrusts and deflection. They are non-center cutting. Primarily for milling die and mold cavities. Sometimes referred to as Taper Degree End Mills or Tapered Milling Cutters.

3 FLUTE

Three flutes remove more material per revolution than two flute end mills. They track straighter, mill at very high feed rates, and create a smoother finish than 2 flute end mills.

REGULAR LENGTH

Single End - 3 Tapered Flutes - Solid Carbide (non-center cutting)

page 277

Single Ball End - 3 Tapered Flutes - Solid Carbide (non-center cutting) page 277

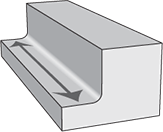

CORNER RADIUS

Corner Radius Style Cut

Corner Radius Style End Mills are designed to mill rounded grooves.

Micro-Grain Solid Carbide Corner Radius End Mills were developed for machining tough work hardening metals, stainless steel, titanium, monel, inconel, and super alloys. It is extremely shock resistant.

2 FLUTE

Using two flutes allows for maximum chip ejection.

REGULAR LENGTH

Single End Corner Radius - 2 Flute - Solid Carbide

page 279

4 FLUTE

Using four flutes provides a finer finish than two flutes and operates with less vibration when run at high speeds.

REGULAR LENGTH

Single End Corner Radius - 4 Flute - Solid Carbide

page 279

MINIATURE DECIMAL SIZE END MILLS

Some jobs require specialized miniature end mills to accomplish specific tasks such as working with jewelry, clocks or models.

MINIATURE LENGTH

Single End Mini-Decimal Size - 2 Flute - Solid Carbide

page 278

Single End Mini-Decimal Size - 4 Flute - Solid Carbide page 278

Double End Mini-Decimal Size - 2 Flute - Solid Carbide page 278

Double End Mini-Decimal Size - 4 Flute - Solid Carbide page 278