REAMERS

Reamers are rotary cutting tools designed

to enlarge and true a hole to size and contour a previously formed

hole. They are available in a variety of styles and sizes for specific

applications.

LONG PILOT ADJUSTABLE HAND REAMERS

HSS - Long Pilot

page 194A

High Speed Steel Long Pilot Adjustable Hand Reamers are designed

for in line reaming when two holes are spaced far apart.

The solid ground pilot uses a “floating” tapered guide sleeve

which is seated in one hole to guide the reamer as it reams the other hole.

The tapered guide sleeve can be used at either end of the other hole.

They are also known Long Pilot Adjustable Blade Reamers,

Adjustable In Line Reamers or Adjustable King Pin Reamers.

ADJUSTABLE HAND REAMERS

HSS

page 194

HSS - Long Pilot page 194A

8 Piece Set page 194

8 Piece Set - Long Pilot page 194A

11 Piece Set page 194

Adjustable Hand Reamers are designed with enough

adjustment to ream almost any odd size hole encountered in reaming.

The blades are made of high speed steel for long life and can be

adjusted by loosening one nut while tightening the other. They

are used mostly for repair work in the field.

HSS - Long Pilot page 194A

High Speed Steel Long Pilot Adjustable Hand Reamers are designed

for in line reaming when two holes are spaced far apart.

The solid ground pilot uses a “floating” tapered guide sleeve

which is seated in one hole to guide the reamer as it reams the other hole.

The tapered guide sleeve can be used at either end of the other hole.

They are also known Long Pilot Adjustable Blade Reamers,

Adjustable In Line Reamers or Adjustable King Pin Reamers.

ADJUSTABLE HAND REAMER SETS

4 Piece Set page 194Sizes 8A to 5A

8 Piece Set page 194

Sizes A to H

8 Piece Set - Long Pilot page 194A

Sizes A to H

11 Piece Set page 194

Sizes A to K

AUTOMOTIVE STEERING & SUSPENSION REAMERS

High Speed Steel (HSS)

page 197A

High Speed Steel Automotive Steering and Suspension Reamers are manufactured with a taper of 1-1/2” per foot. They are designed for rebuilding and repairing automotive suspension systems.

They are used to deburr and enlarge tapered holes for tie rod ends, steering arms, and ball joint applications. They are also referred to as Automotive Taper Reamers or Ball Joint Taper Reamers.

BRIDGE REAMERS

Taper Shank - Heavy Duty - HSS

page 200

Round Shank - Heavy Duty - HSS page 200

High Speed Steel Taper Shank Bridge Reamers are designed for use

in structural steel fabrication bridge work, and ship construction

to line up bolt and rivet holes. Can be used in portable electric

or pneumatic equipment. These tools are also referred to as Boilermaker’s

Reamers, Rivet Hole Reamers, Aligning Reamers, or Construction

Taper Reamers.

NOTE: Because of the heavy duty work involved, some sizes have larger Morse Taper shanks than is usual for the diameter.

NOTE: Because of the heavy duty work involved, some sizes have larger Morse Taper shanks than is usual for the diameter.

Round Shank - Heavy Duty - HSS page 200

High Speed Steel Round Shank Bridge Reamers are designed for

lining up holes in structural steel fabrication bridgework, ship

construction, automotive maintenance, and railroad car manufacture.

Can be used with any 1/2"

3 jaw power tool. Round Shank design helps prevent "whip" caused

by tool-snagging or binding. These tools are also referred to

as Boilermaker’s Reamers, Rivet Hole Reamers, Aligning

Reamers, or Construction Taper Reamers.

NOTE: Because of the heavy duty work involved, some sizes have larger Morse Taper shanks than is usual for the diameter.

NOTE: Because of the heavy duty work involved, some sizes have larger Morse Taper shanks than is usual for the diameter.

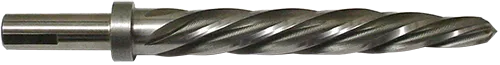

CAR REAMERS

FRACTIONAL SIZES

Round Shank - Fast Sprial Flute - HSS

page 198

360° view

High Speed Steel Fast Spiral Flute Round Shank Car Reamers are designed for lining up holes in structural steel fabrication bridgework, ship construction,

automotive maintenance, and railroad car manufacture.

Short Length makes it useful in close quarters with any

1/2" 3

jaw power tool.

Hex Shank - Helical Flute - HSS page 199 360° view

High Speed Steel Helical Flute Hex Shank Car Reamers are designed to be used in pneumatic equipment for structural steel erection. Their short overall length makes them useful in close quarters.

Combo Hex/Round Shank - Fast Spiral Flute - HSS page 199

High Speed Steel Fast Spiral Flute Combination Hex/Round Shank Car Reamers are designed

for lining up holes in structural steel fabrication

bridgework, ship construction, automotive maintenance,

and railroad car manufacture. Short Length makes

it useful in close quarters with any 1/2"

3 jaw power tool.

Safety Style 1-1/4” hex shank size requires only one size square drive impact wrench socket to use. All ICS Safety Style Hex Shank Reamers are designed to protect against the danger and loss of falling objects such as a reamer. See OSHA 29CFR Part 1926.759 (falling object protection).

Safety Style 1-1/4” hex shank size requires only one size square drive impact wrench socket to use. All ICS Safety Style Hex Shank Reamers are designed to protect against the danger and loss of falling objects such as a reamer. See OSHA 29CFR Part 1926.759 (falling object protection).

Body Bound Bolt Reamers - High Speed Steel (HSS) page 198A

Body Bound Bolt Reamers are designed to prevent the movement of a body bound bolt within the hole. They are manufactured to a tight tolerance slightly under the bolt size and used primarily for shoulder bolts on truck frames.

METRIC SIZES

Metric Round Shank - Fast Sprial Flute - HSS

page 198A

High Speed Steel Fast Spiral Flute Metric Round Shank Car Reamers are designed for lining up holes in structural steel fabrication bridgework, ship construction, automotive maintenance, and railroad car manufacture. Short Length makes it useful in close quarters with any 1/2" 3 jaw power tool.

CHUCKING REAMERS - CARBIDE TIPPED

Fractional - Carbide Tipped

page 190

Carbide Tipped Straight Shank Straight Flute Chucking Reamers are designed for reaming highly abrasive materials and sizing holes that have work-hardened. They are also used when sand or scale is encountered in reaming holes in castings. Tolerance is +.0003 -.0000".

CHUCKING REAMERS - COBALT

Fractional - Cobalt

page 190

Cobalt Straight Shank Straight Flute Chucking Reamers are designed for reaming in tough steels, stainless steel, titanium, and inconel. They can be run about 25% faster than high speed steel and produce a smoother finished hole. Tool life is increased up to 500%.

CHUCKING REAMERS - HIGH SPEED STEEL

FRACTIONAL SIZES

Fractional Sizes - HSS

page 188

High Speed Steel Straight Shank Straight Flute Chucking Reamers are designed for general purpose reaming of most ferrous and non-ferrous metals. The cutting edge is ground with a 45° chamfer angle for easy hole entry. They are also known as Straight Flute Machine Reamers.

Fractional - HSS - Helical Flute page 188

High Speed Steel Straight Shank Helical Flute Chucking Reamers are designed for reaming materials where additional shear is necessary and to improve chip removal in blind holes. The cutting edge is ground with a 45° chamfer angle for easy hole entry. They are also known as Helical Flute Machine Reamers.

Fractional - Extra Length - HSS page 193

High Speed Steel Extra Length Straight Flute Chucking Reamers are designed for reaming and sizing holes in inaccessible places which cannot be

reached with standard length chucking reamers. Various combinations

of diameter and overall lengths are available.

Fractional - Extra Long Flute - Taper Shank - HSS page 193J

High Speed Steel Extra Long Flute Taper Shank Chucking Reamers are designed to fill the needs of users requiring a machine reamer with extra long flutes to ream materials where additional shear is needed. They are manufactured with a 7° - 10° left hand spiral flute and 45° bevel lead for machine use for holes to H7 tolerance. They are also known as Taper Shank Extra Long Fluted Machine Reamers.

Fractional - Expansion - HSS page 193G

High Speed Steel Expansion Chucking Reamers are designed to maintain the initial size by compensating for wear on the cutting end. When the reamer has been worn undersize, it may be expanded oversize by tightening the adjusting screw then reground to size and resharpened on the bevel cutting lead. They should not be considered an adjustable reamer to provide holes of different sizes.

METRIC SIZES

Metric - HSS

page 192

High Speed Steel Metric Straight Flute Chucking reamers are designed for general purpose reaming,. Ground with 45° chamfer.

WIRE GAUGE SIZES

Wire Gauge Sizes - HSS

page 189

High Speed Steel Wire Gauge Size Straight Shank Straight Flute Chucking Reamers are designed for general purpose reaming of most ferrous and non-ferrous metals. The cutting edge is ground with a 45° chamfer angle for easy hole entry.

LETTER SIZES

Letter Sizes - HSS

page 189

High Speed Steel Letter Size Straight Shank Straight Flute Chucking Reamers are designed for general purpose reaming of most ferrous and non-ferrous metals. The cutting edge is ground with a 45° chamfer angle for easy hole entry.

DOWEL PIN SIZES

Dowel Pin Sizes - HSS

page 191

High Speed Steel Straight Shank Straight Flute Dowel Pin Size Chucking Reamers are designed to size holes in preparation for installing dowel pins. Diameter tolerance is +.0000" to -.0002".

SPECIAL DECIMAL SIZES

Special Decimal - HSS

page 192

High Speed Steel Decimal Size Straight Flute Chucking Reamers are designed to remove a very small (.0005 to .001 inch) amount of metal when sizing a hole.

OVER AND UNDER SIZES

Over & Under Sizes - HSS

page 191

High Speed Steel Straight Shank Straight Flute Oversize and Undersize Chucking Reamers are designed for allow a slightly tighter or looser cut for common fractional size chucking reamers. Oversize reamers are +.001" and undersize reamers are -.001" from common fractional sizes of 1/8", 3/16", 1/4", 5/16", 7/16", and 1/2".

SETS

14 Piece Set - High Speed Steel (HSS)

page 193

Dowel Pin Sizes .1230 to .4995

14 Piece Set - High Speed Steel (HSS) page 193

Over & Under Sizes .1240 to .5010

26 Piece Set - High Speed Steel (HSS) page 193

Letter Sizes A to Z

29 Piece Set - High Speed Steel (HSS) page 193

Sizes 1/16 to 1/2 by 64ths

60 Piece Set - High Speed Steel (HSS) page 193

Wire Gauge Sizes 1 to 60

CHUCKING REAMERS - SOLID CARBIDE

FRACTIONAL SIZES

Solid Carbide - Fractional

page 193A

Solid Carbide Straight Shank Straight Flute Chucking Reamers are used for reaming abrasive materials, hard steels up to RC50, aluminum, brass, bronze and plastics. Tolerance: .0001" - +.0003.

METRIC SIZES

Solid Carbide - Metric

page 193B

Solid Carbide Metric Straight Shank Straight Flute Chucking Reamers are used for reaming abrasive materials, hard steels up to RC50, aluminum, brass, bronze and plastics. Tolerance: .0001" - +.0003.

WIRE GAUGE SIZES

Solid Carbide - Wire Gauge Sizes

page 193B

Solid Carbide Wire Gauge Size Straight Shank Straight Flute Chucking Reamers are used for reaming abrasive materials, hard steels up to RC50, aluminum, brass, bronze and plastics. Tolerance: .0001" - +.0003.

LETTER SIZES

Solid Carbide - Letter Sizes

page 193A

Solid Carbide Letter Size Straight Shank Straight Flute Chucking Reamers are used for reaming abrasive materials, hard steels up to RC50, aluminum, brass, bronze and plastics. Tolerance: .0001" - +.0003.

SILVER & DEMING REAMERS

Silver & Deming - Fractional - HSS - 6" Length

page 192A

High Speed Steel Silver and Deming Reamers are designed for general purpose reaming where shorter length and extra rigidity are needed. They are ideal for Bridgeport and hand held applications. Ground with a 45° chamfer.

HAND EXPANSION REAMERS

HSS - Straight Flute

page 195

HSS - Helical Flute - Left Hand Helix page 195

High Speed Steel Straight Flute Hand Expansion Reamers are designed to enlarge reamed holes by a few thousandths. Straight flute is for general purpose reaming.

The pilot and guide on these reamers are ground slightly undersize for clearance

and to guide reamer. The flutes also have a ground starting taper to help guide

reamer into hole. Reamer can be expanded slightly by turning adjusting screw

on and off reamer.

HSS - Helical Flute - Left Hand Helix page 195

High Speed Steel Helical Flute Hand Expansion Reamers are designed

to enlarge reamed holes by a few thousandths. Helical flute,

left hand helix is for reaming keyways and interrupted cut holes.

The pilot and guide on these reamers are ground slightly undersize

for clearance and to guide reamer. The flutes also have a ground

starting taper to help guide reamer into hole. Reamer can be

expanded slightly by turning adjusting screw on and off reamer.

HAND REAMERS

FRACTIONAL SIZES

HSS - Fractional Sizes - Straight Flute

page 196

High Speed Steel Straight Flute Hand Reamers are designed for extreme accuracy and are used by hand for final sizing of drilled holes. Straight flute is for

general purpose reaming. The square shank and fits in a tap wrench. Both styles

of Hand Reamers have a ground starting taper on cutting end for easy entry.

HSS - Fractional Sizes - Helical Flute page 196

High Speed Steel Helical Flute Hand Reamers are designed for

extreme accuracy and are used by hand for final sizing of drilled

holes. Helical flute, left hand helix is for reaming keyways and interrupted cut holes.

The square shank and fits in a tap wrench. Both styles of Hand

Reamers have a ground starting taper on cutting end for easy

entry.

METRIC SIZES

HSS - Metric - Straight Flute

page 196

High Speed Steel Straight Flute Metric Hand Reamers are designed

for extreme accuracy and are used by hand for final sizing of

drilled holes. Straight flute is for general purpose reaming.

The square shank and fits in a tap wrench. Both styles of Hand

Reamers have a ground starting taper on cutting end for easy

entry.

HSS - Metric - Helical Flute page 196

High Speed Steel Helical Flute Metric Hand Reamers are designed

for extreme accuracy and are used by hand for final sizing of

drilled holes. Helical flute, left hand helix is for reaming

keyways and interrupted cut holes. The square shank and fits

in a tap wrench. Both styles of Hand Reamers have a ground starting

taper on cutting end for easy entry.

MACHINE REAMERS

Fractional - Extra Long Flute - Taper Shank - HSS

page 193J

Machine Reamers - Metric Sizes - Extra Long Flute - Taper Shank - HSS page 193K

High Speed Steel Extra Long Flute Taper Shank Chucking Reamers are designed to fill the needs of users requiring a machine reamer with extra long flutes to ream materials where additional shear is needed. They are manufactured with a 7° - 10° left hand spiral flute and 45° bevel lead for machine use for holes to H7 tolerance.

Machine Reamers - Metric Sizes - Extra Long Flute - Taper Shank - HSS page 193K

High Speed Steel Extra Long Flute Taper Shank Metric Chucking Reamers are designed to fill the needs of users requiring a machine reamer with extra long flutes to ream materials where additional shear is needed. They are manufactured with a 7° - 10° left hand spiral flute and 45° bevel lead for machine use for holes to H7 tolerance.

PIPE REAMERS

Pipe Reamers - Taper - HSS - Straight Flute

page 196A

360° view

Pipe Reamers - Taper - HSS - Spiral Flute page 196A

High Speed Steel Straight Flute Taper Pipe Reamers are designed

for use in easy to ream materials. Taper Pipe Reamers are manufactured

with a taper of 3/4" per foot. They are used prior to tapping

dry seal and ANPT threads when high quality threads are required.

Pipe Reamers - Taper - HSS - Spiral Flute page 196A

High Speed Steel Spiral Flute Taper Pipe Reamers are designed

for reaming harder materials where additional shear is needed.

Taper Pipe Reamers are manufactured with a taper of 3/4" per

foot. They are used prior to tapping dry seal and ANPT threads

when high quality threads are required.

REPAIRMAN'S TAPER REAMER

Repairman’s Taper Reamers - Tool Steel

page 187B

360° view

Repairman’s Taper Reamers are designed for removing burs from small holes, tubing, etc. They are also used to enlarge and countersink holes in soft metals, plastics, and similar materials. Used by plumbers, mechanics, electricians, and machinists. Not for use in machine power tools.

SHELL REAMERS

Straight Flute

page 197

360° view

Helical Flute page 197

Arbors page 197

High Speed Steel Straight Flute Shell Reamers are designed to be

used as a chucking reamer for reaming bearings and other similar

work. They are fluted almost their whole length and have a tapered

1/8" per

foot hole to be used with shell reamer arbors. One arbor fits several

sizes of reamers so only 9 sizes of arbors are needed to fit all

sizes of reamers.

Helical Flute page 197

High Speed Steel Helical Flute Shell Reamers are designed to

be used as a chucking reamer for reaming bearings and other similar

work. They are fluted almost their whole length and have a tapered

1/8" per foot hole to be used with shell reamer arbors.

One arbor fits several sizes of reamers so only 9 sizes of arbors

are needed to fit all sizes of reamers.

Arbors page 197

High Speed Steel Shell Reamer Arbors are tapered to fit the hole in the Shell

Reamer. They fit together with slots in the reamer which engage lugs on the arbor for driving power.

TAPER PIN DRILL/REAMERS

Fractional

page 200B

Metric page 201A

High Speed Steel Taper Pin Drill/Reamers are designed to drill and

ream tapered holes in metal to fit taper pins in one operation. They

are made with an included taper of 1 in 48 (1/4" per foot) and

have chip breakers along the cutting edge.

Metric page 201A

High Speed Steel Metric Taper Pin Drill/Reamers are designed

to drill and ream tapered holes in metal to fit taper pins in

one operation. They are made with an included taper of 1" in 50 and have chip breakers along the cutting edge.

TAPER PIN REAMERS

FRACTIONAL SIZES

NOTE: It is recommended that one or more drills should be used prior to reaming.

Fractional taper pin reamer specs and recommended drills.

Straight Flute page 201

High Speed Steel Straight Flute Taper Pin Reamers are for use

in easy to ream materials. They are manufactured

with a taper of 1/4" per foot. They are used to ream holes

into which standard taper pins will fit. The point of each reamer

will enter hole reamed by next smaller size. Hole to be reamed

should be a few thousandths smaller than the small diameter of

the finished reamed hole. Square shank allows hand reamers to

be held in a tap wrench or vise, depending on whether the reamer

or the part is rotated.

Spiral Left Hand Flute page 201

High Speed Steel Spiral Left Hand Flute Taper Pin Reamers are for use

in hard to ream materials and where the reamer tends to wedge

itself. They are manufactured

with a taper of 1/4" per foot. They are used to ream holes

into which standard taper pins will fit. The point of each reamer

will enter hole reamed by next smaller size. Hole to be reamed

should be a few thousandths smaller than the small diameter of

the finished reamed hole. Square shank allows hand reamers to

be held in a tap wrench or vise, depending on whether the reamer

or the part is rotated.

Helical Left Hand Flute page 201

High Speed Steel Helical Left Hand Flute Taper Pin Reamers are for machine

reaming of holes for taper pins on a production basis. Helical

design throws the chips forward to alleviate packing of the flutes.

They are manufactured with a taper of 1/4" per foot. They

are used to ream holes into which standard taper pins will fit.

The point of each reamer will enter hole reamed by next smaller

size. Hole to be reamed should be a few thousandths smaller than

the small diameter of the finished reamed hole.

METRIC SIZES

Metric taper pin reamer specs and recommended drills.

Straight Flute - Metric page 201A

High Speed Steel Straight Flute Metric Taper Pin Reamers are

for use in easy to ream materials. They are manufactured

with a taper of 1" in 50. They are used to ream holes

into which standard taper pins will fit. The point of each reamer

will enter hole reamed by next smaller size. Hole to be reamed

should be a few thousandths smaller than the small diameter of

the finished reamed hole. Square shank allows hand (straight

& spiral) reamers to be held in a tap wrench or

vise, depending on whether the reamer or the part is

rotated.

Helical Left Hand Flute - Metric page 201A

High Speed Steel Helical Left Hand Flute Metric Taper Pin Reamers are for machine reaming of holes for taper pins on a production basis. Helical design throws the chips forward to alleviate packing of the flutes.

TOWER BOLT REAMERS

Left Hand Flute

196A

360° view

High Speed Steel Tower Bolt Reamers are designed for

lining up bolt holes on cell phone towers, wind mills, and transmission

towers. They have three flats on the shank for use in 1/2" three

jaw power tools and pneumatic equipment. The extra short length

makes them more useful in close quarters.